What is a cylinder head, and why is it so vital to your engine’s performance? This essential component sits atop your engine block, sealing the combustion chamber while housing critical parts like valves and spark plugs. Understanding its role can help you spot potential issues and keep your vehicle running smoothly—so let’s dive deeper into its function and importance.

What Is Cylinder Head

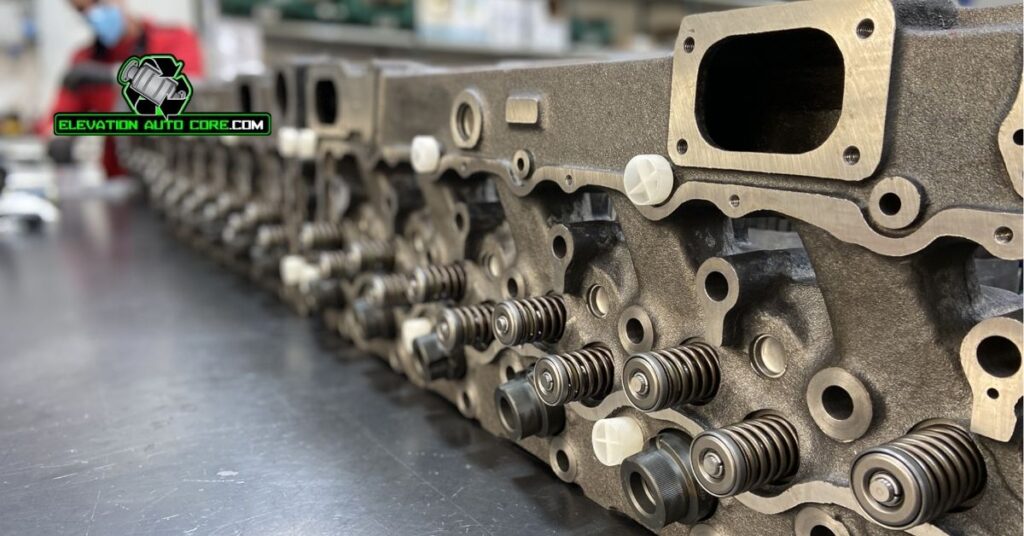

A cylinder head forms a key component of an internal combustion engine. It sits on top of the engine block and seals the combustion chamber. This ensures efficient compression and combustion during engine operation.

Parts integrated into the cylinder head include valves, spark plugs, and sometimes camshafts. Valves manage the intake of air-fuel mixture and the expulsion of exhaust gases. Spark plugs initiate the combustion process by igniting the fuel-air mixture.

Materials like aluminum or cast iron are used to manufacture cylinder heads due to their durability and heat resistance. The design and material choice directly impact engine efficiency, heat dissipation, and longevity.

Cylinder heads also have coolant and oil passages. These passages enable efficient engine cooling and lubrication, preventing overheating and reducing wear.

Functions Of A Cylinder Head

A cylinder head performs multiple tasks to ensure the engine operates efficiently. It plays an essential role in various processes, from sealing the combustion chamber to managing heat dissipation.

Sealing The Combustion Chamber

The cylinder head creates a tight seal with the engine block, preventing gas leakage during combustion. This seal is critical for maintaining compression levels and ensuring efficient power generation. Incorporating components like the head gasket enhances this sealing process, reducing energy loss.

Facilitating Air And Fuel Flow

Air-fuel mixture movement relies on the cylinder head’s integrated passages. Intake and exhaust valves, located here, regulate the flow of air and fuel into the chamber while allowing exhaust gases to exit. Proper flow ensures optimized combustion, directly impacting engine performance and efficiency.

Heat Dissipation

Efficient temperature regulation depends significantly on the cylinder head. Built-in coolant passages circulate fluid to remove excess heat from the combustion process. Materials like aluminum and cast iron improve thermal conductivity, helping maintain safe engine operating conditions.

Types Of Cylinder Heads

Cylinder heads come in various designs, each suited to exact engine requirements. These designs differ in their configuration and placement of components like valves and camshafts.

Flathead Cylinder Head

Flathead cylinder heads feature a simple design, where valves are positioned next to the cylinder within the engine block. This design reduces manufacturing costs due to its straightforward construction. You often find flathead designs in older engines and small machinery. While they optimize space, they generally provide less efficient airflow and combustion compared to modern designs. Heat dissipation is also limited because of the compact valve placement.

Overhead Valve (OHV) Cylinder Head

Overhead valve heads position the valves above the cylinder, with the camshaft located within the engine block. This structure uses pushrods to control valve movement, offering advantages in durability and simplicity. OHV designs are common in V-type engines, especially for trucks and SUVs. They deliver better power-to-size ratios while maintaining a relatively compact build. Though they handle higher stress well, their additional components often result in more mechanical noise and complexity.

Overhead Camshaft (OHC) Cylinder Head

Overhead camshaft heads incorporate the camshaft directly above the valves, eliminating the need for pushrods. This configuration improves engine efficiency and allows higher RPMs. Single overhead cam (SOHC) systems are simpler and lighter, while double overhead cam (DOHC) systems provide better valve control and performance. OHC designs dominate modern engines, particularly in high-performance and fuel-efficient vehicles. Even though improved functionality, they can be more complex and expensive to manufacture and maintain.

Material Used In Cylinder Heads

Cylinder heads rely on exact materials to handle extreme conditions, maintaining engine durability and performance.

Aluminum Cylinder Heads

Aluminum is commonly used for manufacturing cylinder heads due to its light weight and excellent thermal conductivity. This material efficiently dissipates heat, helping to prevent engine overheating during extended operation. Aluminum cylinder heads are often found in modern engines where weight reduction and improved fuel efficiency are priorities. But, aluminum can be more prone to warping at high temperatures compared to cast iron, emphasizing the need for precise engineering.

Cast Iron Cylinder Heads

Cast iron offers superior strength and resistance to wear, making it a durable choice for cylinder heads. Its ability to withstand high stress and thermal loads makes it suitable for heavy-duty applications. Cast iron cylinder heads also provide better sealing due to their rigidity, which can improve compression efficiency. On the downside, cast iron is significantly heavier than aluminum and has lower heat dissipation properties, which might lead to slower cooling processes in demanding conditions. This material is often used in engines prioritizing durability and cost-effectiveness over weight and thermal efficiency.

Importance Of Cylinder Head In Engines

The cylinder head plays a central role in engine performance by sealing the combustion chamber and housing vital components. Without it, the engine would fail to compress the air-fuel mixture effectively, compromising combustion and reducing power output. Its presence ensures that the combustion process operates efficiently.

This component supports critical engine operations like air intake, exhaust gas expulsion, and heat management. Valves integrated within the cylinder head control the flow of intake air and exhaust gases, directly influencing performance and emissions. Proper regulation of these flows enhances fuel efficiency and engine responsiveness.

Coolant and oil passages within the cylinder head are essential for thermal regulation. They prevent the engine from overheating by circulating cooling fluids and enable smooth operation by lubricating moving parts. This thermal management supports long-term engine durability.

Materials used in manufacturing the cylinder head significantly affect its reliability. Aluminum models excel in heat dissipation, improving thermal conductance for modern lightweight engines. Conversely, cast iron heads offer better wear resistance, supporting heavy-duty engines. Both materials ensure the cylinder head withstands high pressures and temperatures during operation.

Efficient sealing between the cylinder head and engine block is indispensable for compression retention. Tight seals created with components like the head gasket ensure that no gases escape during combustion. Maintaining optimal compression is critical for producing maximum engine power while limiting energy loss.

Operational precision in the cylinder head also optimizes airflow and fuel mixing. Combustion efficiency improves when the air-fuel mixture reaches the cylinders in the right proportions, directly affecting engine output and reducing emissions. This operational synergy reinforces the cylinder head’s importance in engine performance.

Common Issues With Cylinder Heads

Cylinder heads are prone to various problems that can disrupt engine performance if not addressed promptly. Understanding these issues helps you identify potential signs of failure and ensure timely maintenance.

Cracks And Leaks

Cracks often develop in cylinder heads due to high thermal and mechanical stress. These fractures can occur in areas surrounding coolant or oil passages, leading to internal or external leaks. Coolant leaks can cause overheating or damage to other engine components. Oil leaks may reduce lubrication, increasing wear on vital parts.

Leaking head gaskets are a common result of cracked cylinder heads. They disrupt the combustion chamber’s seal, causing loss of compression and reduced engine efficiency. White smoke from the exhaust or visible coolant mixing with oil are typical indicators of such issues.

Warping Due To Overheating

Warping arises when excessive heat causes the cylinder head to deform. High temperatures can weaken aluminum or cast iron materials, altering the cylinder head’s original shape. This deformation prevents proper sealing between the head and block, compromising compression.

Symptoms of warped cylinder heads include engine misfires, overheating, or pressure leaks. A failing coolant system or prolonged overheating conditions heighten the risk of warping and intensify damage over time.

Conclusion

A cylinder head is more than just a component; it’s a cornerstone of your engine’s performance and efficiency. Its intricate design and critical functions ensure smooth operation, proper combustion, and effective heat management, all of which are essential for a reliable vehicle.

By understanding its role and recognizing potential issues like cracks or leaks, you can take proactive steps to maintain your engine’s health. Whether through regular inspections or timely repairs, caring for your cylinder head helps extend your engine’s lifespan and optimize performance.