What is a serpentine belt, and why does it matter for your vehicle? This essential component keeps critical systems like your alternator, power steering, and air conditioning running smoothly. Without it, your car wouldn’t function properly—so understanding its role can save you from unexpected breakdowns. Keep reading to learn why this belt is so vital and how it impacts your car’s performance.

What Is A Serpentine Belt?

A serpentine belt is a single, continuous belt that powers multiple components in your vehicle. It connects the engine crankshaft to systems like the alternator, power steering pump, and air conditioning compressor. This belt ensures these components function smoothly by transferring mechanical energy.

Most modern vehicles rely on serpentine belts due to their efficiency. Unlike older systems with multiple belts, the serpentine belt uses a tensioner to maintain proper tightness. This design reduces wear and increases durability.

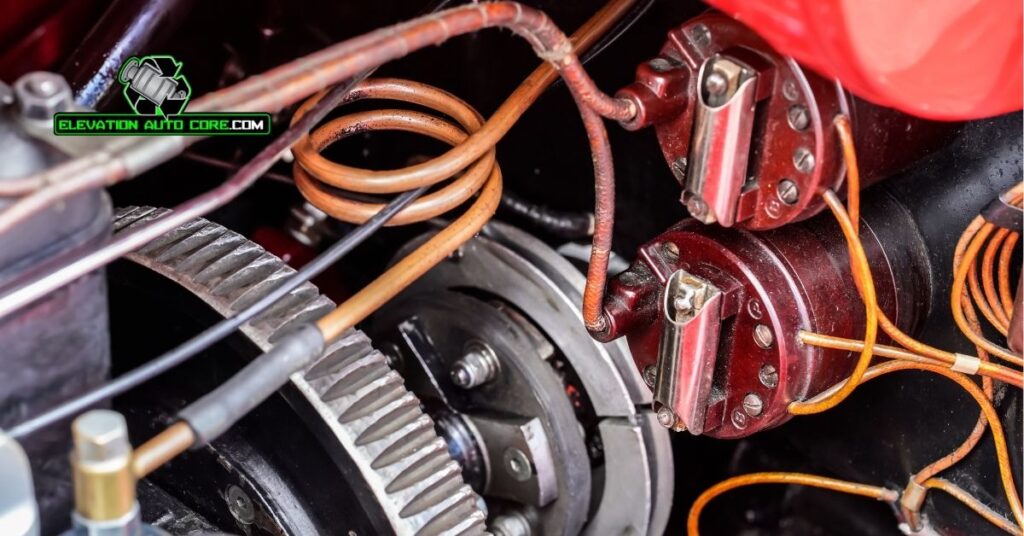

Visible on the front of the engine, the belt is typically made of rubber with grooves for better grip. These grooves align with the pulleys on various engine parts. Regular inspection is essential to spot cracks, fraying, or signs of wear that can lead to failure.

Functions Of A Serpentine Belt

The serpentine belt handles critical functions in your vehicle by driving several key systems. Its design ensures smooth mechanical energy transfer for optimal performance.

Powering Essential Components

A serpentine belt supplies power to multiple vehicle accessories. It drives the alternator, which keeps the battery charged and electrical systems functioning. Your power steering pump relies on this belt to provide easy steering control. It also powers the air conditioning compressor, ensuring a comfortable cabin environment. In some vehicles, it drives the water pump, a vital component for regulating engine temperatures to prevent overheating.

Ensuring Engine Efficiency

Energy transfer to essential systems occurs without excess energy loss due to the serpentine belt’s efficient design. It reduces the need for multiple belts, simplifying operation and improving overall reliability. Proper alignment and tension through a belt tensioner reduce friction, extending both belt and engine component lifespans. Damage or wear on the serpentine belt disrupts this efficiency, leading to decreased performance or component failure. Regular inspection helps maintain these benefits.

Common Signs Of A Failing Serpentine Belt

Recognizing signs of a failing serpentine belt helps prevent costly repairs and breakdowns. Pay attention to these symptoms to keep your vehicle running smoothly.

Squealing Noise

Unusual noises often indicate belt problems. A high-pitched squeal while starting the engine or during acceleration signals slipping or misalignment. Contamination from oil or fluids can worsen this issue, reducing belt efficiency.

Visual Wear And Tear

Physical damage is a common sign of failure. Cracks, fraying, or visible grooves indicate the belt is deteriorating. Missing chunks of rubber suggest advanced wear, requiring immediate replacement to avoid further damage to connected components.

Loss Of Power Assistance

A failing serpentine belt impacts essential systems. If steering feels heavy or power-assisted features like the alternator stop functioning, the belt might be slipping or broken. Inspect the belt right away when power delivery becomes inconsistent.

Importance Of Regular Maintenance

Regular maintenance keeps the serpentine belt functioning effectively and prevents unexpected failures. Maintaining the belt ensures essential vehicle systems like the alternator and power steering operate smoothly.

Inspection Tips

Inspect the belt visually for cracks, fraying, or missing rubber pieces. Look for any gloss or shine on the surface, which could indicate wear or slipping. Listen for squealing sounds during engine operation as a sign of misalignment or tension issues. Check the tensioner and pulley system to ensure proper alignment, as these components directly impact the belt’s performance. Schedule an inspection every 30,000 to 60,000 miles based on the manufacturer’s recommendations.

Replacement Guidelines

Replace the belt when important wear or damage is detected. Use a proper-sized replacement belt to avoid improper fit or performance issues. Adjust tension correctly by ensuring the tensioner provides adequate pressure, which reduces excess strain on the system. Follow the vehicle’s maintenance guide to replace key components like the tensioner or pulleys if they exhibit wear. Typically, serpentine belts last 60,000 to 100,000 miles, but exact intervals depend on vehicle usage and conditions.

Conclusion

Understanding the role and maintenance of your serpentine belt is key to keeping your vehicle running smoothly and avoiding unexpected issues. By staying attentive to signs of wear and scheduling regular inspections, you can ensure this essential component continues to perform efficiently.

A well-maintained serpentine belt not only enhances your car’s reliability but also prevents costly repairs down the road. Prioritize its care, and you’ll keep your vehicle’s critical systems functioning at their best for miles to come.