What is a rear main seal, and why does it matter for your vehicle? This critical component sits at the back of your engine, sealing the crankshaft to prevent oil leaks that could lead to costly repairs. Understanding its role can help you spot potential issues early and keep your engine running smoothly. Keep reading to learn more about how this small part plays a big role in your car’s performance.

What Is A Rear Main Seal

A rear main seal is a critical engine component designed to prevent oil leaks by sealing the end of the crankshaft. It sits between the engine and the transmission, encasing the back of the crankshaft where it exits the engine block. This seal plays a vital role in maintaining proper lubrication throughout the engine system.

The rear main seal is usually made from durable rubber or silicone material. Its construction ensures it can withstand high engine temperatures and pressure over extended periods. Most vehicles use a circular seal that fits snugly around the crankshaft’s rear end.

Leaks from the rear main seal often start as minor issues. These leaks can lead to important oil loss if left unchecked, affecting engine lubrication and performance. Recognizing its importance helps you keep the engine running efficiently.

Function And Importance Of The Rear Main Seal

The rear main seal is essential for your vehicle’s engine, ensuring smooth operation by preventing oil from escaping the crankshaft area. Understanding its function helps identify potential problems early.

Role In Engine Performance

This seal plays a vital role in maintaining the engine’s efficiency. It ensures that engine oil stays within the lubrication system, allowing the crankshaft to rotate smoothly. Without a functioning seal, oil leaks can disrupt lubrication, causing friction and excessive wear on internal components. Over time, such issues might lead to engine overheating or complete failure. Properly sealed crankshafts support balanced performance by maintaining consistent oil flow.

Preventing Oil Leaks

The reinforcement of the rear main seal’s design prevents oil from leaking between the crankshaft and the engine. Durable materials like rubber or silicone allow it to handle high pressure and extreme heat during constant engine operation. Leaks, even small ones, can reduce engine oil levels and lead to poor lubrication. Addressing leaks quickly stops oil buildup around the transmission bell housing, protecting nearby components from damage.

Common Problems With Rear Main Seals

Rear main seal issues can lead to important engine problems if left unresolved. Understanding the causes and symptoms of failure helps prevent costly repairs and protects engine performance.

Causes Of Seal Failure

Exposure to wear over time is a primary cause of rear main seal failure. The seal’s materials degrade due to constant engine heat and pressure. Poor installation practices during seal replacement often cause alignment issues, leading to leaks. Lack of regular engine maintenance, such as oil changes, allows debris and sludge to accumulate, which can damage the seal’s surface. High crankcase pressure caused by blocked ventilation also puts excessive strain on the seal, increasing the risk of damage.

Signs And Symptoms Of A Damaged Seal

An oil leak near the engine-to-transmission connection is a common indicator of seal damage. You’ll often notice oil puddles under the vehicle after parking. Lower engine oil levels without any visible leaks on other components suggest the rear main seal as the source. Increased oil consumption often accompanies rear seal issues, leading to more frequent refills. A burning oil smell results from oil dripping onto hot engine parts. In some cases, you may observe smoke coming from the transmission bell housing due to oil seepage.

Repairing Or Replacing A Rear Main Seal

Repairing or replacing a rear main seal requires careful attention due to its location between the engine and transmission. Proper tools and techniques ensure a successful repair while protecting surrounding components.

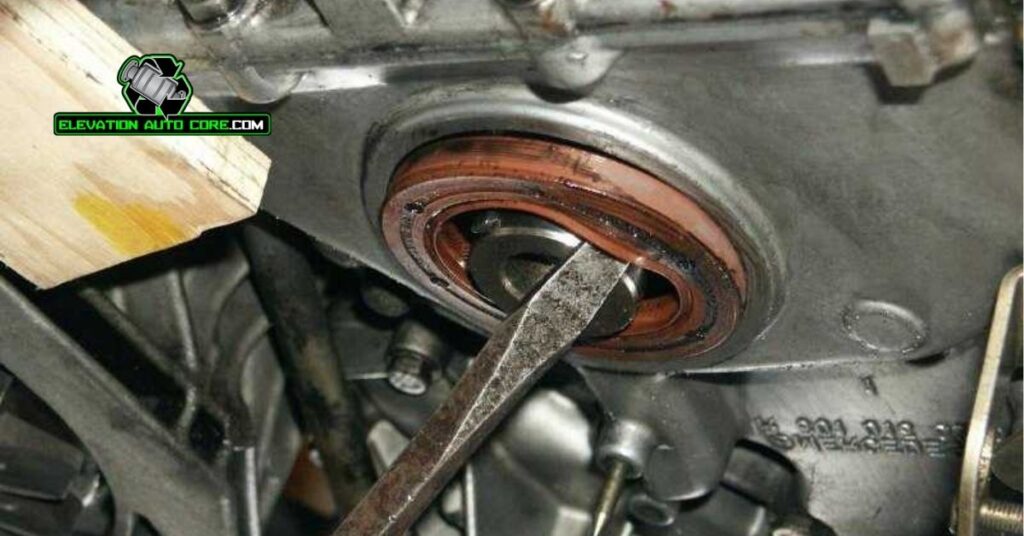

Tools And Techniques Required

Specialized tools simplify the process of rear main seal replacement. You need a seal puller to remove the damaged seal without harming nearby parts. A seal driver ensures precise installation of the new seal. Basic hand tools, including wrenches and screwdrivers, assist in removing the transmission or other obstructing components.

Preparation is equally important. Clean the area around the seal to prevent debris contamination during installation. Apply engine-safe lubricant to the new seal’s edges for smoother insertion. Carefully align the new seal to avoid misplacement, which can cause future leaks. If high crankcase pressure contributed to the failure, check the ventilation system for clogs or damage.

DIY Vs Professional Repair

Attempting a DIY rear main seal replacement depends on your mechanical knowledge and tool availability. If you’re skilled in automotive repairs and have the required tools, DIY can save labor costs. But, removing the transmission and accessing the seal is complex and time-consuming.

Professional repair services offer expertise and efficiency. Mechanics diagnose related issues, such as crankshaft damage or ventilation system clogs, during the replacement process. While professional services can be costly, they reduce the risk of mistakes that may cause further engine damage.

Preventing Rear Main Seal Issues

Regular maintenance and informed choices play key roles in avoiding rear main seal problems. By adopting proactive measures, you can extend the lifespan of your seal and reduce the risk of costly repairs.

Maintenance Tips

Inspecting your vehicle at regular intervals helps identify early signs of rear main seal wear. Look for oil leaks near the engine-to-transmission area or check oil levels frequently to detect unexplained decreases. Cleaning the crankcase ventilation system ensures pressure remains balanced, which prevents excessive strain on the seal.

Performing timely oil changes using manufacturer-recommended viscosity oils maintains proper lubrication. Using high-quality oil with cleaning additives reduces sludge buildup, decreasing the likelihood of seal degeneration. Monitoring and replacing worn engine components like gaskets or seals that interact with the crankshaft can also minimize undue stress.

Choosing Quality Seals

Selecting a durable seal when replacement is necessary safeguards your engine against future leaks. Choose seals made of high-grade materials, such as silicone or fluoroelastomer, which can withstand extreme temperatures and pressures. Products from reputable brands typically undergo stringent quality checks, making them a reliable choice.

Verifying the compatibility of the rear main seal with your exact vehicle ensures proper fit and function. Look for seals designed to provide enhanced oil resistance and longevity. Consulting a trusted mechanic or reviewing product recommendations from your vehicle’s manufacturer helps make an well-informed choice.

Conclusion

Understanding the rear main seal’s role in your vehicle is essential for maintaining engine health and performance. By staying proactive with regular maintenance and addressing issues promptly, you can prevent costly repairs and extend the life of your engine. Whether you choose DIY repairs or professional services, ensuring the seal is in top condition will keep your engine running smoothly and efficiently. Prioritize quality parts and proper care to protect your vehicle and avoid unnecessary complications down the road.