What is a camshaft position sensor, and why does it matter for your vehicle’s performance? This small yet crucial component monitors the camshaft’s position, ensuring your engine’s timing and fuel injection work seamlessly. Without it, your car could face misfires or even fail to start—keep reading to understand its role and importance.

Entities: camshaft position sensor, vehicle, engine, timing, fuel injection, misfires.

What Is A Camshaft Position Sensor

A camshaft position sensor is an engine component that tracks the rotation of the camshaft. It gathers data on the camshaft’s position in relation to the crankshaft. This information is sent to the engine control unit. Using this data, the engine control unit manages ignition timing and fuel delivery.

Its design typically includes a magnetic or Hall-effect sensor. These designs detect changes in a spinning component’s magnetic field. As a result, the camshaft position sensor monitors positional changes with precision.

Modern vehicles rely heavily on this sensor for efficient engine operation. Faulty readings can disrupt fuel injection or spark timing.

How Does A Camshaft Position Sensor Work

A camshaft position sensor monitors the camshaft’s rotational position and communicates with the engine control unit for precise engine operation. Its functionality ensures accurate ignition timing and fuel injection.

Key Components Of The Sensor

Every camshaft position sensor includes a sensing element, connector pins, and a housing unit. The sensing element, often magnetic or Hall-effect based, detects camshaft motion. Connector pins allow electrical communication with the engine control unit. Durable housing protects the internal parts from heat, moisture, and debris.

Basic Working Principle

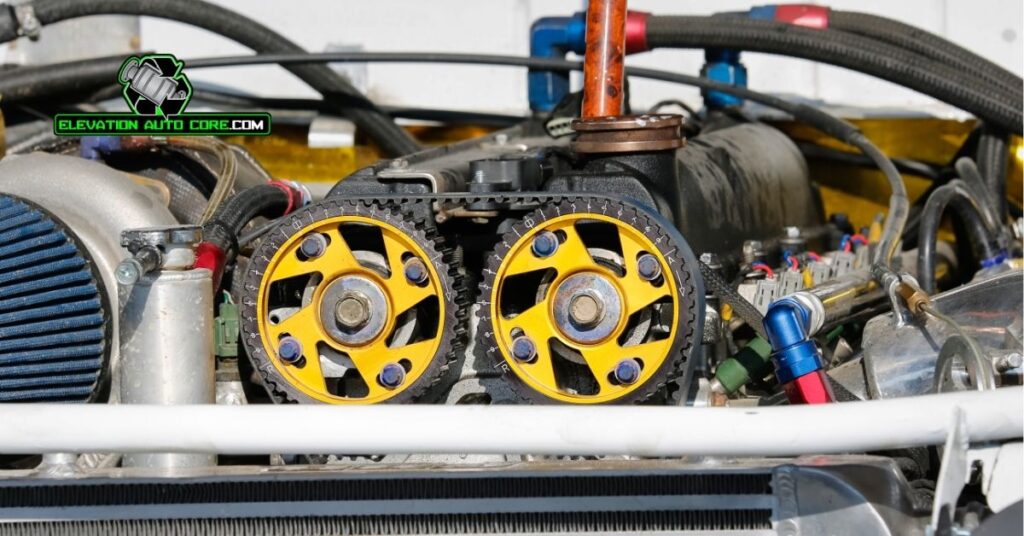

A camshaft position sensor detects the camshaft’s position by sensing changes in a magnetic field caused by camshaft rotation. Once detected, the sensor converts this data into an electrical signal. The engine control unit receives this signal, synchronizing fuel injection and ignition timing with the crankshaft’s position.

Importance Of Camshaft Position Sensor In Vehicles

The camshaft position sensor plays a critical role in modern vehicles. It supports engine precision by relaying accurate data for combustion timing.

Improving Engine Efficiency

Optimal fuel combustion depends on accurate data from the camshaft position sensor. By monitoring camshaft movement, the sensor ensures precise ignition and fuel delivery. This synchronization reduces fuel wastage and improves mileage. Faulty sensor readings, but, compromise efficiency, leading to irregular fuel consumption.

Impact On Vehicle Performance

Performance consistency relies on a functional camshaft position sensor. Engine misfires, power loss, or stalling occur if the sensor fails to communicate correctly with the engine control unit. Reliable sensor feedback supports smooth acceleration and consistent power delivery. Modern engines depend on this integration to avoid performance degradation.

Common Symptoms Of A Failing Camshaft Position Sensor

A failing camshaft position sensor can impact your vehicle’s performance and functionality. Identifying the symptoms early is crucial to prevent further damage or expensive repairs.

Engine Performance Issues

Your vehicle might experience frequent engine misfires when the camshaft position sensor malfunctions. These misfires occur because inaccurate sensor signals disrupt ignition timing and fuel delivery. You may notice rough idling or unexpected stalling, especially during acceleration. Poor fuel efficiency could also be a result, as incorrect timing leads to improper combustion. Difficulty starting the engine often points to a failing sensor, commonly due to an inability to detect the camshaft’s position accurately.

Warning Lights And Error Codes

The check engine light may illuminate if the camshaft position sensor sends faulty signals. Modern vehicles rely on sensors to detect irregularities, triggering this warning to indicate an issue. Diagnostic trouble codes, such as P0340 or P0341, typically appear alongside this warning. These codes specifically relate to camshaft sensor circuit failures, signaling a need for immediate attention. Retrieving error codes with an OBD-II scanner helps confirm the problem and ensures accurate troubleshooting.

Diagnosing And Repairing Camshaft Position Sensor Issues

Addressing camshaft position sensor issues promptly ensures your engine operates efficiently. A malfunction can lead to stalling, misfires, or difficulty starting, so diagnosing and repairing it is crucial.

Tools Needed For Diagnosis

Gathering the right tools simplifies diagnosing camshaft sensor failures. A digital multimeter is essential for testing electrical signals. An OBD-II scanner helps retrieve diagnostic trouble codes like P0340 or P0341. Basic hand tools, including screwdrivers and socket sets, are necessary for accessing the sensor. A flashlight can assist in identifying the sensor’s location in low-visibility areas. Using a rag ensures you can clean debris before working.

Step-By-Step Repair Process

Start by locating the camshaft position sensor, typically near the engine cylinder head or timing cover. Always disconnect the vehicle’s battery before working to avoid electrical accidents. Use the OBD-II scanner to identify codes that verify sensor issues. Inspect the sensor and its wiring for visible damage, such as frayed wires or corroded connectors. If no damage is visible, test the sensor’s voltage output using a multimeter.

Remove the faulty sensor with appropriate tools after confirming failure. Ensure you clean the mounting area before installing the replacement to prevent debris interference. Install the new sensor by aligning it with the mounting hole and securing it tightly. Reconnect the sensor’s wiring harness and vehicle battery. Check for proper operation by rescanning the system with the OBD-II scanner to ensure no error codes remain.

Preventive Maintenance Tips For A Camshaft Position Sensor

Regular checks ensure your camshaft position sensor operates efficiently. Inspect the sensor and its connections periodically for signs of corrosion or damage. Dirt accumulation on the sensor can disrupt its functionality, so clean the area around it when needed.

Maintain proper wiring conditions by ensuring the harness and connectors remain intact. Electrical issues often stem from damaged or loose connections. Use dielectric grease to protect electrical connectors from moisture and debris.

Schedule routine diagnostics to catch potential issues early. An OBD-II scan can identify minor faults before they escalate into important problems. These scans also help monitor sensor feedback and maintain optimal engine performance.

Use high-quality parts for replacements if necessary. Inferior components can lead to premature failures or inaccurate signals. Following the manufacturer’s specifications guarantees compatibility and longevity.

Replace engine oil and air filters regularly to prevent debris from reaching the sensor. Contaminants can interfere with its measurements. Keeping the engine environment clean enhances sensor reliability.

Avoid prolonged exposure to harsh temperatures whenever possible. Extreme heat or cold can degrade internal sensor components, reducing lifespan. Park your vehicle in shaded areas or garages to mitigate temperature fluctuations.

Focus on these preventive measures to reduce wear and avoid unexpected engine issues caused by camshaft position sensor failure.

Conclusion

Understanding the camshaft position sensor’s role in your vehicle can help you maintain optimal engine performance and avoid costly repairs. This small yet vital component ensures precise timing for ignition and fuel delivery, directly impacting efficiency and reliability.

By staying proactive with regular inspections and addressing any issues promptly, you can extend the lifespan of your sensor and enhance overall engine performance. Investing in quality parts and proper maintenance will save you time and money while keeping your vehicle running smoothly for years to come.