What Is A Camshaft

A camshaft is a crucial engine component designed to manage the timing of valve operations. It operates by converting rotational motion into linear motion to control intake and exhaust valves. Positioned within the engine block or cylinder head, it plays a direct role in engine functionality.

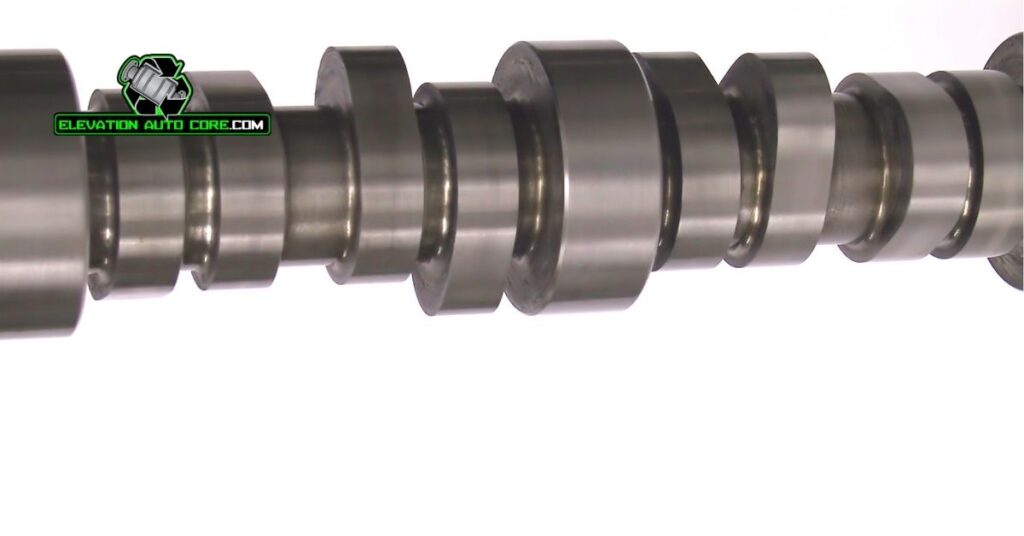

Each camshaft includes lobes that make contact with valve lifters, pushing them to open or close valves. The number of lobes corresponds to the engine’s valve count, ensuring precise operations. Camshafts can be made of hardened steel or cast iron, chosen based on engine requirements.

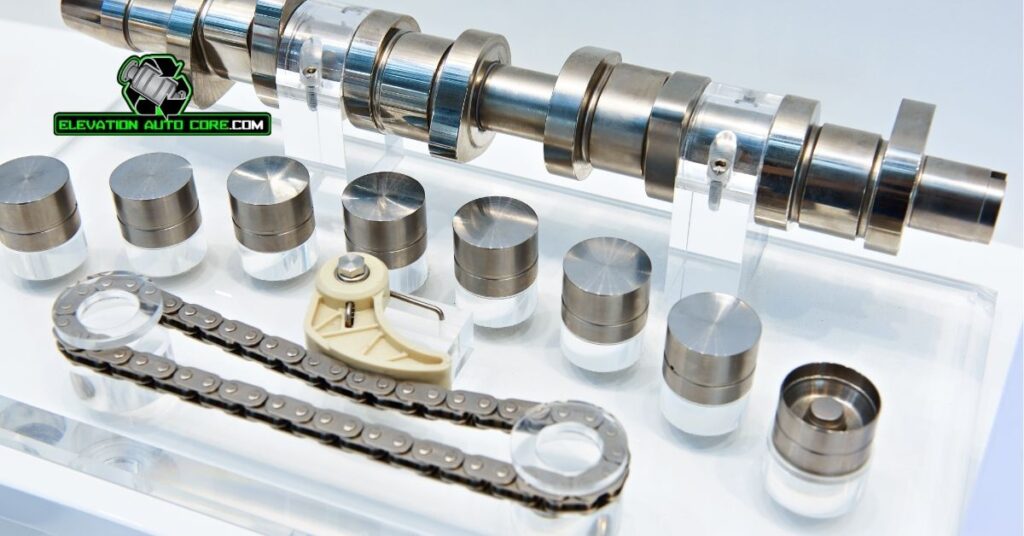

The camshaft connects to the crankshaft through timing belts, chains, or gears. This connection ensures synchronization between the two components, facilitating accurate combustion cycles. Performance vehicles commonly feature dual overhead camshafts for improved efficiency and power.

Variable valve timing technologies often integrate with the camshaft to enhance engine performance. This allows adjustments to valve timing based on acceleration, improving fuel efficiency and power output under different conditions.

How A Camshaft Works

A camshaft plays an essential role in regulating the intake and exhaust valve operations in an engine. Its function ensures precise timing and synchronization for optimal combustion performance.

Function In Engine Operation

The camshaft translates rotational motion from the crankshaft into linear motion. Each cam lobe interacts with the valve lifters to manage their movement, controlling the opening and closing of the valves. Intake valves open to allow air-fuel mixture into the combustion chamber, while exhaust valves release burnt gases. The camshaft’s role ensures this process happens accurately for every engine cycle.

Importance Of Timing

Precise timing between the camshaft and crankshaft is critical for engine efficiency. A timing belt, chain, or gear connects these components to maintain synchronization. If the valves do not operate in harmony with piston movement, combustion efficiency decreases, and engine performance suffers. Advanced systems like variable valve timing use the camshaft to adjust valve operation dynamically, improving efficiency and power output during acceleration.

Types Of Camshafts

Camshafts come in various designs to suit exact engine configurations and performance needs. The primary types include flat tappet, roller, and overhead camshafts.

Flat Tappet Camshafts

Flat tappet camshafts use lifters with flat contact surfaces to connect with the cam lobe. These are common in older or traditional engines. The flat surface helps maintain direct contact, ensuring consistent valve timing. They often require regular maintenance, like proper lubrication, to prevent excessive wear and tear. Budget-friendly and simple in design, flat tappet camshafts are popular in standard performance applications.

Roller Camshafts

Roller camshafts feature roller lifters that use bearings to reduce friction. Designed for durability and efficiency, these camshafts allow smoother operation at higher engine speeds. They’re widely used in modern engines due to improved power output and extended longevity. The rolling mechanism minimizes wear and optimizes timing precision. High-performance engines often integrate roller camshafts for enhanced reliability under extreme conditions.

Overhead Camshafts

Overhead camshafts are mounted above the engine’s cylinders, directly controlling the valves. This placement eliminates the need for pushrods, improving mechanical efficiency. Single and dual overhead camshaft configurations offer flexibility; dual setups, for example, provide better valve control in high-performance engines. Overhead camshafts are a staple in modern vehicles, delivering enhanced precision and power output. Their design supports advanced technologies, including variable valve timing, for optimized engine performance.

Materials Used In Camshaft Construction

Camshafts rely on durable materials to endure the stresses of engine operation. Manufacturing methods and material selection are critical for ensuring their longevity and performance.

Cast Iron

Cast iron is frequently used for camshaft production due to its wear resistance and casting versatility. Its ability to withstand friction makes it ideal for engines operating under standard conditions. Manufacturers often harden its surface through treatments like induction hardening to further enhance durability. Economical and efficient, cast iron camshafts are commonly found in everyday vehicles.

Steel

Steel is another widely used material known for its strength and durability. Its ability to handle high-stress loads suits high-performance engines. Alloy steel, incorporating elements like chromium or molybdenum, is often chosen to bolster hardness and tensile strength. Precision machining of steel camshafts ensures consistent performance in modern engines. Performance cars and heavy-duty vehicles usually benefit from steel camshafts due to their resilience under extreme conditions.

Factors To Consider When Choosing A Camshaft

Selecting the right camshaft directly affects engine performance, efficiency, and durability. Prioritizing exact factors helps ensure compatibility and desired outcomes.

Engine Compatibility

Verify the camshaft matches your engine’s design and specifications. Engines vary in configuration, such as single or dual overhead camshafts, which dictate compatibility requirements. Always consider the valve train setup, whether it’s a flat tappet or roller lifter system. Choose materials and dimensions that align with your engine’s manufacturing standards to avoid mechanical failures or inefficiencies. Confirm synchronization support with your timing components, including belts, chains, or gears.

Performance Goals

Define your engine’s performance purpose before choosing a camshaft. Higher lift camshafts deliver increased airflow, suitable for racing or high-performance applications. For daily-use engines, opt for moderate lift and duration to balance power and fuel efficiency. Use variables like lobe separation angle to match camshaft specifications with low-end torque or high-speed power needs. Engines with advanced systems, like variable valve timing, may adapt to broader camshaft profiles, expanding your options.

Common Issues With Camshafts

Camshafts, even though their durability and precision design, can experience problems that impact engine performance. Identifying these issues early helps maintain engine efficiency and prevents costly repairs.

Wear And Tear

The camshaft operates under high stress, making wear a common issue. Excessive friction between the cam lobes and valve lifters causes metal degradation. Over time, worn lobes reduce valve lift, leading to decreased airflow and diminished engine power. Insufficient lubrication exacerbates this problem, increasing the risk of premature wear. Regular oil changes with high-quality engine oil help minimize wear.

Cracks can develop when the camshaft endures repeated stress, particularly in performance engines. These cracks compromise engine integrity and may result in failure if not addressed promptly. Routine inspections during maintenance intervals ensure wear or damage is detected and resolved early.

Timing Problems

Camshaft timing issues can disrupt valve synchronization. Misaligned timing between the camshaft and crankshaft leads to improper valve functioning, affecting combustion efficiency. Timing chain or belt wear often causes this misalignment. Symptoms like rough idling or misfires may signal timing faults requiring immediate attention.

Faulty variable valve timing systems can also affect camshaft performance. These systems depend on precise adjustments to optimize engine output. Malfunctioning actuators or sensors prevent accurate timing adjustments, diminishing fuel efficiency and power. Addressing these problems involves diagnosing and repairing any defective components to restore operation.

Conclusion

Understanding the role of the camshaft helps you appreciate its impact on engine performance and efficiency. From its precise control over valve timing to its influence on power output, the camshaft is a critical component that ensures your engine operates smoothly and reliably.

Whether you’re maintaining a standard vehicle or optimizing a performance engine, choosing the right camshaft and keeping it in good condition is essential. Regular inspections and proper maintenance go a long way in preventing issues and extending the lifespan of this vital part.