What are lifters in a car engine, and why do they matter for your vehicle’s performance? These small yet crucial components play a vital role in ensuring your engine runs smoothly and efficiently. If you’re curious about how they work and their impact on your car, keep reading to uncover their importance and how they contribute to your engine’s functionality.

What Are Lifters In A Car Engine

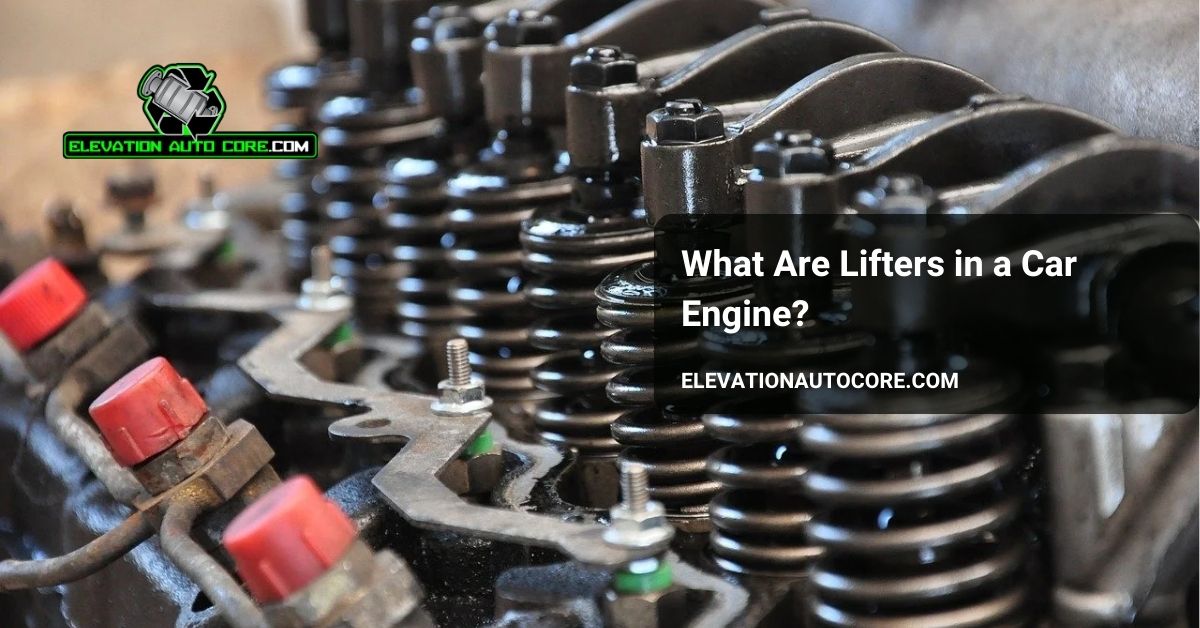

Lifters, also known as valve lifters or tappets, are essential parts within the valve train of a car engine. They help the transfer of motion from the camshaft to the engine’s valves, enabling efficient combustion. Each lifter ensures proper synchronization between the camshaft lobes and the rocker arms.

These components come in two main types: hydraulic and solid lifters. Hydraulic lifters automatically adjust to maintain the correct valve clearance, reducing noise and wear. Solid lifters, by contrast, require manual adjustments but offer better high-performance capabilities.

In modern engines, lifters contribute significantly to achieving precise timing and optimal engine efficiency. Their function minimizes metal-on-metal contact, lowering friction and preventing internal damage. Ensuring lifters remain operational is vital for preserving engine performance and longevity.

Types Of Lifters

Lifters are vital components in a car engine’s valve train, and their type significantly affects performance and maintenance. Each has unique features suited for exact applications.

Hydraulic Lifters

These lifters automatically adjust valve clearance, ensuring consistent operation. They use engine oil to maintain contact between the camshaft and valve, reducing noise and wear. Hydraulic lifters are ideal for everyday vehicles due to their low maintenance and reliability.

Solid Lifters

You must manually adjust these lifters to maintain valve clearance. They provide better stability at higher RPMs, making them suitable for racing or high-performance engines. Solid lifters require regular tuning but offer enhanced durability under extreme conditions.

Roller Lifters

These lifters include a small roller at the base to reduce friction. This design improves efficiency and longevity, especially in high-performance engines. Roller lifters work well with aggressive camshaft profiles, allowing greater power output.

Flat Tappet Lifters

Flat tappet lifters have a flat surface in contact with the camshaft. They are commonly found in older or standard engines. While cost-effective and straightforward, they require proper lubrication to avoid excessive wear and maintain performance.

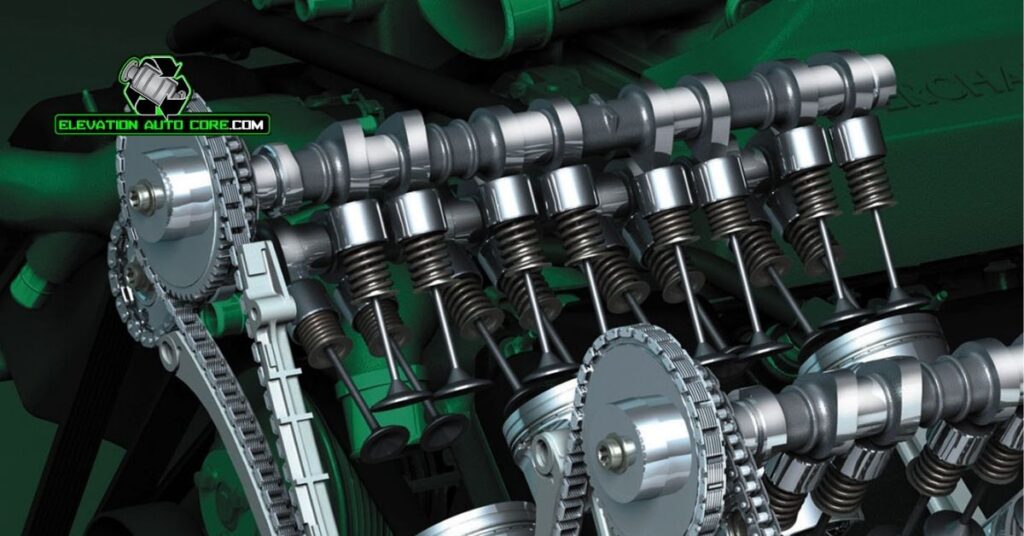

How Lifters Function In A Car Engine

Lifters in a car engine operate as intermediaries in the valve train, transferring motion from the camshaft to the valves. Their precise function directly impacts engine efficiency, timing, and overall performance.

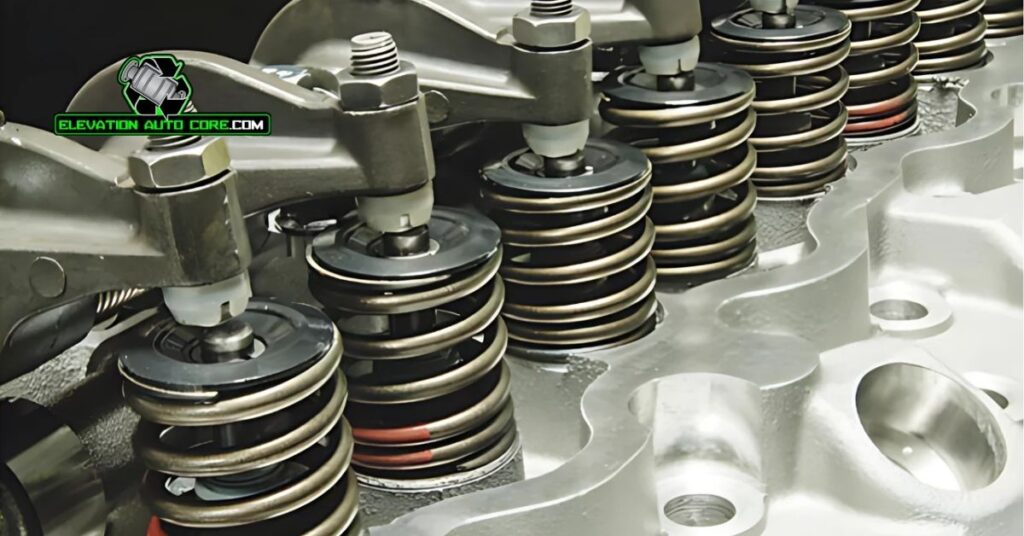

Role In Valve Operation

Lifters link the camshaft to the pushrods or valves, ensuring smooth motion transfer. When the camshaft rotates, its lobes exert force on the lifters, initiating valve movement. This action enables the engine to control airflow into and out of the combustion chamber. Hydraulic lifters automatically adjust to compensate for clearance changes, ensuring consistent valve operation. Solid lifters, though requiring manual adjustment, provide reliable performance under high-stress conditions. Roller lifters reduce friction during valve actuation with their rolling mechanism, making them beneficial for high-performance engines. Flat tappet lifters, found in older engines, depend critically on proper lubrication to prevent wear during valve operation.

Lifters And Engine Performance

Well-functioning lifters improve engine durability and efficiency. Hydraulic lifters minimize maintenance needs while maintaining consistent valve timing, essential for daily vehicles. Solid lifters, though demanding more attention, stabilize operation at elevated RPMs, making them favorable for racing engines. Roller lifters boost efficiency by reducing energy losses in high-output setups. Flat tappet lifters, even though being more sensitive to wear, provide a lower-cost option for standard engines. Maintaining optimal lifter performance prevents friction-related damage, ensures effective combustion, and supports prolonged engine life.

Common Issues With Lifters

Lifters in a car engine are prone to wear and malfunction over time. Understanding these issues helps maintain engine performance and prevent costly repairs.

Signs Of Worn Out Lifters

Unusual engine noise often indicates worn lifters. A ticking or tapping sound, especially during acceleration, suggests improper operation. Misfires can occur when malfunctioning lifters fail to open or close valves correctly.

Reduced engine performance is another sign. Faulty lifters disrupt the smooth transfer of motion between the camshaft and valves, leading to power loss. Excessive exhaust smoke points to combustion issues, potentially caused by lifter problems.

Causes Of Lifters Malfunction

Poor lubrication frequently causes lifter issues. Insufficient oil or degraded oil quality increases friction, leading to wear. Accumulation of dirt or sludge within the lifters hinders their functionality.

Mechanical wear is common in solid lifters that require regular adjustments. Prolonged use without proper maintenance accelerates degradation. Overloading or high-stress conditions, such as in racing engines, also contribute to lifter failure.

Maintenance And Replacement Tips

Keeping your lifters in good condition ensures smooth engine operation and prevents costly repairs. Regular checks and timely replacements are key to maintaining their functionality.

When To Inspect Lifters

Frequent engine noises like ticking or tapping during acceleration often signal lifter issues. Monitor your engine’s performance for unusual changes, as reduced efficiency can indicate lifter wear. Look out for excessive exhaust smoke, which can be linked to lifter malfunctions. Inspect the lifters during routine oil changes to catch problems caused by poor lubrication or mechanical wear. Engines under high stress or used in performance settings may require more frequent checks.

Steps For Replacement

Start by locating the lifters within the engine, typically positioned in the valve train. Remove the engine’s valve cover to access the components. Drain the oil and clean the area to avoid debris contamination. Follow the manufacturer’s guide to removing accessories, like the pushrods or rocker arms, connected to the lifters. Carefully extract the worn lifters with the appropriate tools. Lubricate the new lifters before installing them to reduce friction. Reassemble the engine components as per the manual, ensuring precise alignment. Run the engine briefly to verify smooth operation and check for any unusual noises.

Conclusion

Understanding lifters and their role in your car engine is essential for maintaining optimal performance and longevity. Whether you’re dealing with hydraulic, solid, roller, or flat tappet lifters, each type has unique benefits suited to exact driving needs.

By staying proactive with regular inspections and addressing signs of wear early, you can avoid costly repairs and ensure your engine runs smoothly. Proper maintenance not only enhances efficiency but also extends the life of your engine components, keeping your vehicle reliable for years to come.