What is a camshaft in an engine, and why does it matter? This crucial component controls the timing of your engine’s valves, ensuring smooth performance and efficiency. Whether you’re a car enthusiast or just curious about how engines work, understanding the camshaft’s role will give you a clearer picture of what keeps your engine running.

What Is Camshaft In Engine

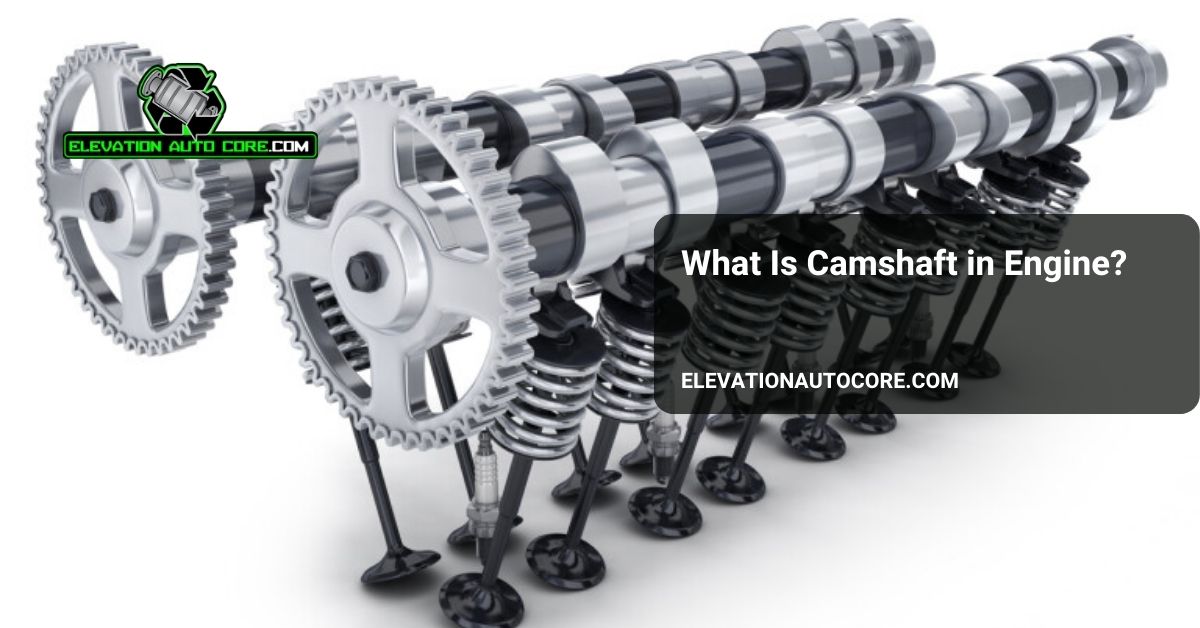

A camshaft is a mechanical component in an internal combustion engine that coordinates the timing of valve operations. It performs this task by converting rotational motion into linear motion, enabling precise control over intake and exhaust valves.

Its primary function is to open and close engine valves at exact intervals during the engine cycle. Located either at the top of the cylinder head or within the engine block, the camshaft design varies based on the engine type.

The camshaft’s lobes are shaped to match the engine’s needs, impacting power, efficiency, and performance. High-performance engines often use camshafts with specialized profiles to optimize airflow and combustion.

Purpose Of Camshaft In Engine

The camshaft ensures precise timing of valve movements, which is critical for efficient engine operation. It directly affects engine performance by controlling air-fuel intake and exhaust gas expulsion.

Role In Combustion

Control over valve timing allows the camshaft to optimize the combustion process. It regulates the intake valve to allow an appropriate air-fuel mixture into the combustion chamber. Once combustion is complete, the camshaft ensures the exhaust valve opens to expel burnt gases. By maintaining this cyclical process, it maximizes power output and fuel efficiency. In high-performance engines, camshaft adjustments enhance combustion characteristics for greater acceleration and torque.

Synchronization With Crankshaft

The camshaft synchronizes with the crankshaft to maintain engine timing. These components operate together through a timing belt, chain, or gears. This alignment ensures that the camshaft’s valve activity matches the piston positions dictated by the crankshaft. Without this synchronization, valve and piston interactions could result in engine damage. In dual overhead camshaft (DOHC) setups, advanced synchronization improves valve control and enables higher rotational speeds for better performance in modern engines.

Types Of Camshafts

Different types of camshafts are designed to meet exact engine requirements. These variations affect engine performance, valve timing precision, and overall functionality.

Overhead Vs Pushrod Camshafts

Overhead camshafts (OHC) sit above the cylinder head and directly control the valve movements. This setup eliminates the need for pushrods and relies on a timing belt or chain for synchronization. It provides higher efficiency and precise valve timing, which is ideal for high-performance engines.

Pushrod camshafts, also called in-block camshafts, are located inside the engine block. They use pushrods to transfer motion from the camshaft to the rocker arms above the cylinder head. This design is simpler and smaller, making it common in traditional V8 engines but less suited to high-revving or modern compact engines.

Flat Tappet Vs Roller Camshafts

Flat tappet camshafts use a flat lifter surface to contact the camshaft lobe. They offer a cost-effective option suitable for basic engines. But, they experience higher friction, leading to faster wear and reduced efficiency compared to their roller counterparts.

Roller camshafts feature lifters with a roller on the contact surface, reducing friction significantly. This design enhances durability and engine performance, particularly in advanced or high-performance engines. Reduced friction also helps optimize fuel efficiency and power delivery.

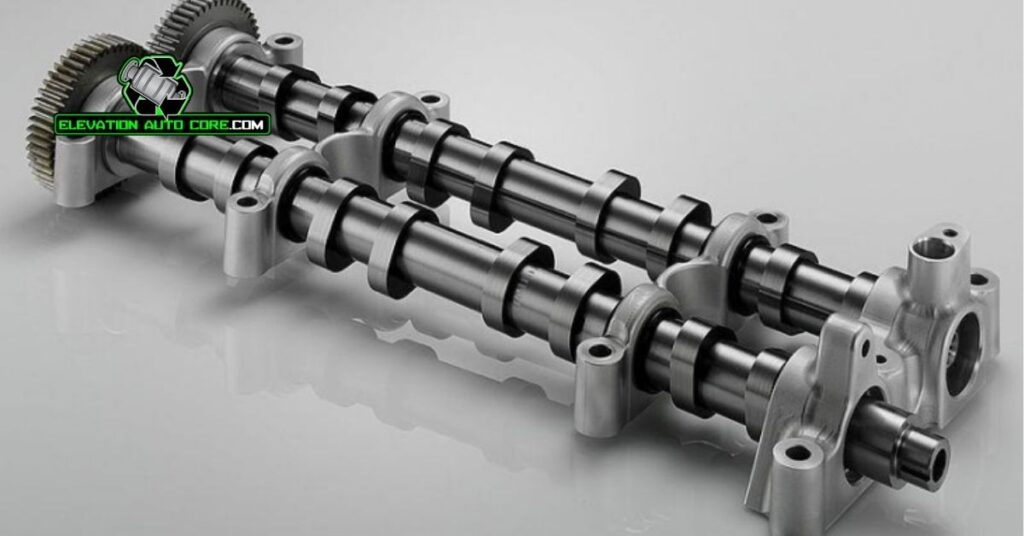

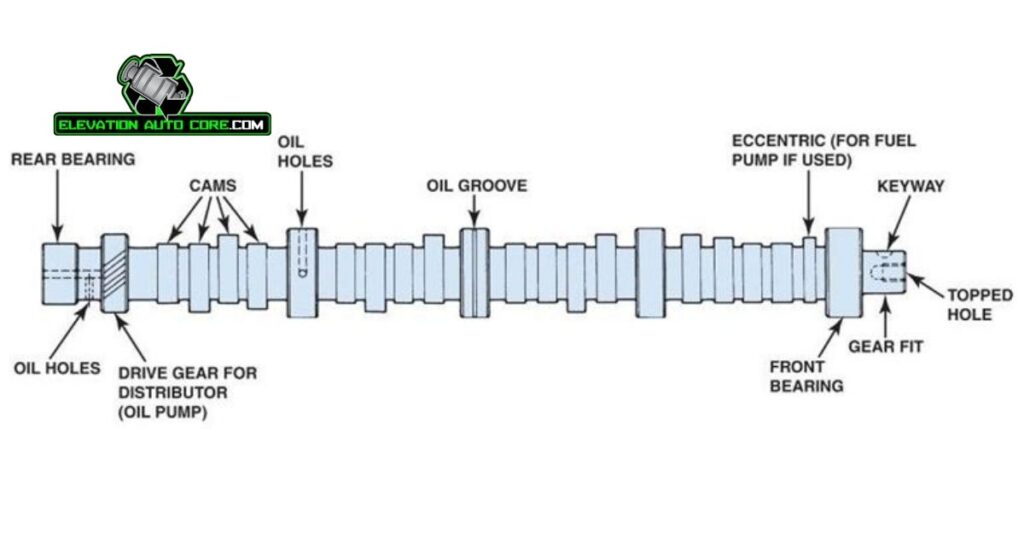

Components Of A Camshaft

The camshaft has several critical components that work together to control valve timing and ensure optimal engine performance. Each part serves a exact purpose, contributing to the efficiency and functionality of the engine.

Lobes And Their Function

Lobes are the most essential parts of the camshaft. These uniquely shaped projections determine the timing, duration, and lift of valve operations. As the camshaft rotates, the lobes push against valve lifters or rocker arms, opening the intake and exhaust valves. The precise shape and placement of the lobes directly impact airflow into and out of the engine. Engines designed for high performance often feature specialized lobe profiles to increase horsepower and torque.

Bearing Journals

Bearing journals support the camshaft and ensure its smooth rotation within the engine. These cylindrical sections rest on bearings that reduce friction and wear over time. Properly functioning journals maintain the camshaft’s alignment and prevent unnecessary strain on other engine components. The number and size of bearing journals depend on the engine’s design and the camshaft’s location, such as in overhead or pushrod configurations.

How Camshafts Affect Engine Performance

Camshafts play a central role in determining engine performance by managing valve operation dynamics and synchronizing engine components. Their design and functionality directly relate to speed, efficiency, and overall timing accuracy.

Impact On Speed And Efficiency

Improved airflow within the cylinders increases engine efficiency. Camshafts dictate how much air-fuel mixture enters the combustion chamber and how quickly exhaust gases exit. High-performance camshafts with optimized lobe designs allow for greater airflow, which enhances power output and fuel combustion.

Valve timing precision contributes significantly to speed. Engines designed for high RPMs rely on camshaft profiles that accommodate faster valve movement, maximizing torque and acceleration. For example, in racing engines, camshaft profiles create rapid transitions between intake and exhaust cycles, increasing the engine’s capability to generate power at higher rotational speeds.

Efficiency optimization occurs when camshafts reduce energy losses. Roller camshafts, for instance, minimize friction compared to flat tappet designs, preserving more energy for engine output. This can result in better mileage and prolonged component durability in everyday driving scenarios.

Influence On Engine Timing

Valve operation timing impacts all aspects of combustion. Camshafts ensure intake valves open at the right moment to draw in the air-fuel mixture and close before compression begins. Similarly, exhaust valves release combustion gases precisely as piston movement concludes, maintaining efficiency.

Synchronization between the camshaft and crankshaft is integral. Through timing chains, belts, or gears, the camshaft aligns its rotation with the engine cycle, ensuring valves operate in harmony with piston positions. If this synchronization falters, performance drops significantly and damage risks increase.

Dual overhead camshaft setups allow independent control of intake and exhaust valves. In modern engines, this separation adds flexibility in adjusting timing, especially under varying load conditions. It leads to cleaner combustion, greater rotational freedom, and overall better engine performance for both daily drivers and high-performance vehicles.

Maintenance And Common Issues Of Camshafts

Proper maintenance of the camshaft is essential for engine performance and longevity. Recognizing wear and adopting preventive measures can minimize costly repairs.

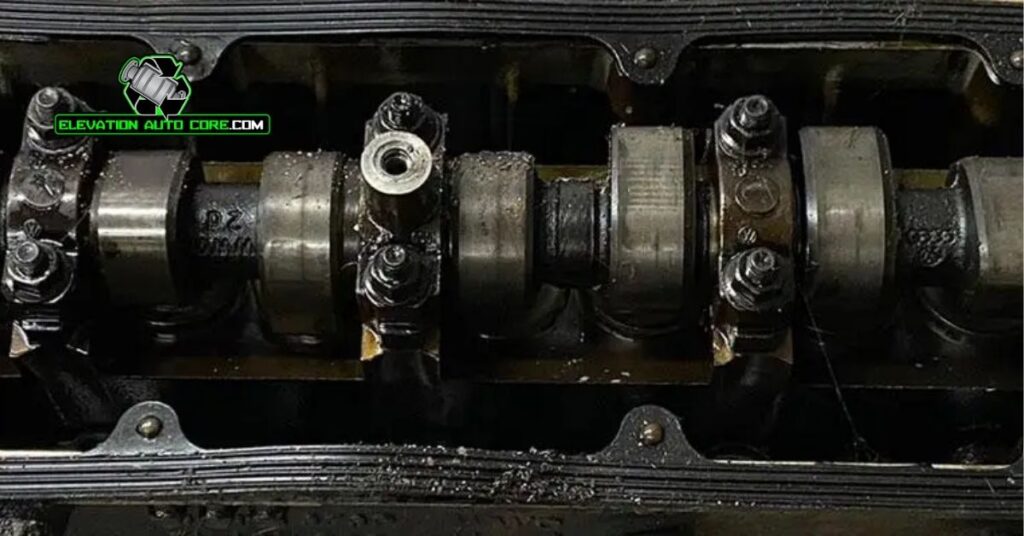

Signs Of Wear And Tear

You might notice unusual engine noises, such as ticking or knocking, caused by worn lobes or bearings. A decrease in engine power or efficiency often points to camshaft issues that impact valve timing and airflow. If oil contamination is present, it could accelerate camshaft wear by damaging the lobes and journals. Visible damage, like grooves or pitting on the camshaft surface, signals excessive friction or improper lubrication.

Severe cases might result in misfires when valve timing is disrupted, affecting combustion processes. Monitoring these signs enables early intervention before important damage occurs.

Tips For Longevity

Regular oil changes ensure the camshaft is properly lubricated, reducing friction and minimizing wear. Using high-quality engine oil specifically designed for your vehicle can further enhance lubrication and improve component durability. Inspect the timing belt or chain periodically, as a malfunctioning timing mechanism can compromise synchronization and stress the camshaft.

Avoid prolonged high RPMs during operation whenever possible, as they increase camshaft strain and can accelerate wear. Cleaning or replacing air filters regularly prevents debris from entering the engine, protecting the camshaft from contaminants. Ensure the valve clearance is adjusted correctly, as improper spacing can overload the camshaft and connected parts.

Conclusion

Understanding the camshaft’s role in your engine gives you valuable insight into how critical components work together to ensure performance and efficiency. Its precise control over valve timing directly impacts power, fuel economy, and overall engine health.

Whether you’re maintaining your vehicle or exploring ways to optimize performance, keeping the camshaft in good condition is essential. Regular maintenance and attention to potential issues can help you avoid costly repairs and extend your engine’s lifespan.