What is a drum brake, and why does it still play a crucial role in vehicle safety today? This time-tested braking system has been around for decades, offering durability and reliability in various applications. Whether you’re curious about its mechanics or its relevance in modern vehicles, understanding drum brakes helps you appreciate the engineering behind safe driving.

What Is Drum Brake

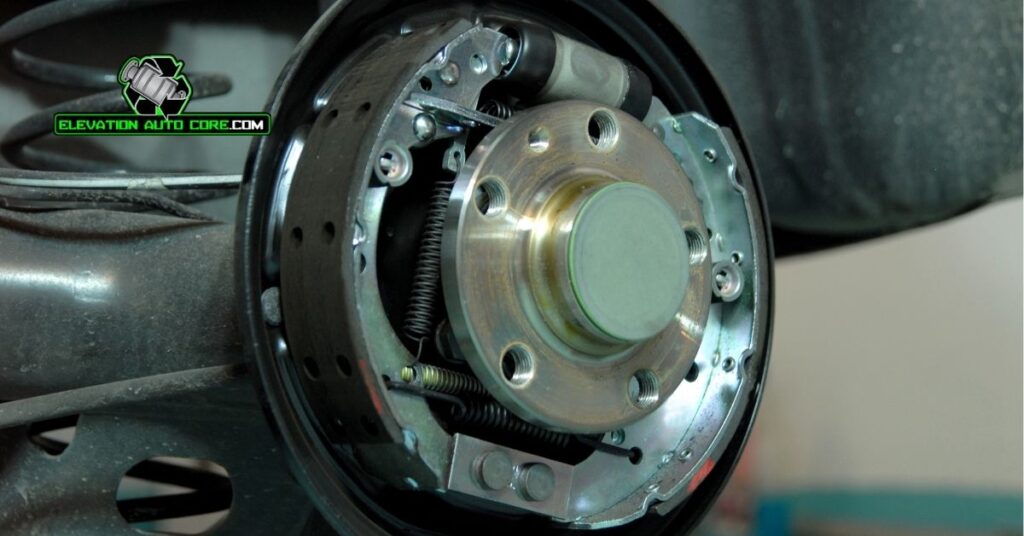

A drum brake is a type of braking system that uses friction to slow or stop a vehicle. It consists of a drum-shaped housing attached to the wheel, within which brake shoes press against the inner surface to create friction. These components work together to convert kinetic energy into heat, reducing wheel rotation.

The structure includes a drum, brake shoes, return springs, and a wheel cylinder. As the driver presses the brake pedal, hydraulic fluid forces the wheel cylinder to push the brake shoes against the drum. This action generates the necessary friction to decelerate the vehicle.

Drum brakes are often used in rear wheels of many vehicles, particularly where cost efficiency and durability are important. They are also common in commercial applications like buses and trucks due to their longevity and ability to handle heavier loads. Compared to disc brakes, drum brakes offer a more enclosed design, which can provide protection against environmental contaminants like dirt and water.

Regular maintenance ensures their optimal performance, as excessive heat or worn-out components can impair functionality.

Components Of Drum Brake

Drum brakes consist of several key components working together to provide effective braking. Each component plays a exact role in ensuring the system operates efficiently.

Brake Drum

The brake drum houses the internal components and serves as the contact surface for the brake shoes. Made from cast iron or steel, it handles high temperatures generated during braking. Its design allows it to rotate with the wheel while maintaining durability against friction.

Brake Shoes

Brake shoes press against the inner surface of the drum to create friction and slow the vehicle. These curved metal components are lined with friction material for effective braking. The lining wears over time and needs regular inspection to maintain performance.

Wheel Cylinder

The wheel cylinder converts hydraulic pressure from the brake pedal into mechanical force. Situated at the top of the drum assembly, it pushes the brake shoes outward when activated. Its dual-piston design ensures balanced pressure distribution across the shoes.

Return Springs

Return springs retract the brake shoes to their original position after braking. These tensioned springs prevent unnecessary contact between the shoes and drum. Properly functioning springs reduce wear and improve overall brake efficiency.

Adjustment Mechanism

The adjustment mechanism maintains optimal clearance between the brake shoes and drum. This component compensates for wear by gradually extending the shoes. Regular checks ensure it operates correctly, promoting consistent braking performance.

How Drum Brakes Work

Drum brakes operate by converting hydraulic pressure into mechanical force, allowing the vehicle to decelerate efficiently. They depend on precise engagement and release to ensure consistent performance.

Captivating The Brake

Pressing the brake pedal initiates the braking process. Hydraulic fluid flows from the master cylinder into the wheel cylinder inside the drum brake assembly. The wheel cylinder pushes the brake shoes outward, pressing them against the rotating drum’s inner surface. This contact generates friction, slowing the drum and connected wheel. The process distributes braking force evenly, essential for maintaining vehicle control.

Releasing The Brake

The return springs play a vital role in retracting the brake shoes. Once the driver releases the brake pedal, the hydraulic pressure decreases within the wheel cylinder. This reduction allows the springs to pull the brake shoes back to their resting position, away from the drum’s surface. The gap created between the shoes and the drum prevents unnecessary friction, promoting efficiency and minimizing wear.

Advantages Of Drum Brakes

Drum brakes offer impressive durability, making them a reliable choice for heavy-duty vehicles like trucks and buses. Their design allows them to withstand high pressure and handle heavier loads without compromising performance.

You benefit from lower production and maintenance costs with drum brakes. These brakes are simpler to manufacture, and their components are less expensive to replace compared to other braking systems like disc brakes.

Drum brakes provide better performance in diverse vehicle applications. They are particularly effective when used for parking brakes or in vehicles requiring enhanced braking force at the rear wheels.

More friction contact area increases their efficiency. The larger surface area within the drum enhances heat dissipation and braking power, especially under consistent use in commercial vehicles.

Self-energizing action improves energy efficiency during braking. Force generated when the brake shoes press against the drum reduces the required effort from hydraulic systems.

Effective dirt and debris protection safeguards their internal components. The closed design of drum brakes prevents contaminants from directly interfering with the braking mechanism, ensuring longer operational life in various environmental conditions.

Disadvantages Of Drum Brakes

Drum brakes are prone to overheating during prolonged or heavy use, which reduces braking efficiency. Excess heat causes brake fade, making them less reliable for consistent performance compared to other systems. Their enclosed design, while protective, traps heat inside, increasing the risk of diminished effectiveness on steep descents or in high-temperature environments.

Maintenance demands can also be a drawback. You may find it challenging to inspect and repair internal components without removing the drum, making the process more labor-intensive. Frequent servicing becomes necessary for vehicles subjected to heavy use to prevent issues like uneven wear or hydraulic leaks.

Water and debris entering the drum can degrade functionality. Even though the closed design offers some protection, water can reduce friction between the shoes and the drum, while debris can cause uneven braking or damage to components. This susceptibility impacts reliability in adverse weather or rough off-road conditions.

Brake shoe adjustment needs periodic attention. Improper adjustment affects braking balance and can lead to premature wear of parts, causing additional repair costs. The system relies on more components compared to disc brakes, increasing the likelihood of wear and eventual failure of individual parts over time.

Application Of Drum Brakes

Drum brakes are widely used in the rear wheels of passenger cars, especially where cost effectiveness and reliability matter. Many commercial vehicles like buses and trucks use drum brakes due to their capacity to endure heavier loads and maintain functionality over extended periods. Their ability to handle intense braking conditions efficiently makes them suitable for these applications.

This braking system is a preferred choice for parking brakes in various vehicles. Because drum brakes provide a larger friction surface area, they generate the necessary holding power essential for securing stationary vehicles, even on inclines. Compact construction and reliable performance under static load lend themselves well to this purpose.

Armored vehicles and similar heavy-duty machinery often employ drum brakes for their robust and durable design. The enclosed structure protects critical components from dirt and debris, making them highly effective for off-road applications or operations in dusty environments.

Two-wheeled vehicles like motorcycles often incorporate drum brakes in the rear. Cost efficiency, lightweight structure, and simplicity of operation meet exact requirements in this segment. This choice allows manufacturers to balance performance and production costs effectively.

In industrial settings, certain machinery with rotational parts relies on drum brakes. Some examples include conveyor systems and material handling equipment, where the braking system needs to ensure controlled operations and prevent damage or accidents. The adaptable design fits seamlessly into these mechanical systems.

Conclusion

Drum brakes remain a vital component in various vehicles and industries, offering durability, cost efficiency, and reliable performance. Their ability to handle heavy loads and serve as effective parking brakes underscores their importance in modern applications. By understanding how they work and maintaining them properly, you can ensure they continue to perform at their best. Whether you’re exploring their mechanics or considering their advantages, drum brakes demonstrate the enduring value of thoughtful engineering.