What do carburetors do, and why are they so crucial for engines? These mechanical devices mix air and fuel in just the right proportions to ensure your engine runs smoothly and efficiently. Whether you’re restoring a classic car or curious about how older engines function, understanding carburetors opens the door to better performance and maintenance. Keep reading to uncover how they work and why they matter.

Understanding Carburetors

Carburetors play a critical role in maintaining the efficiency and functionality of older engines. They ensure a balanced mix of air and fuel, which is essential for combustion and engine performance.

The Role Of Carburetors In Engines

Carburetors mix air and fuel in precise ratios for combustion processes. This mixture is sent to the engine’s cylinders, where it’s ignited to generate power. Improving fuel atomization is another key function, which ensures the fuel is broken into fine droplets for better combustion efficiency. In engines without modern electronic fuel injection systems, carburetors regulate airflow to manage engine speed and performance under different operating conditions.

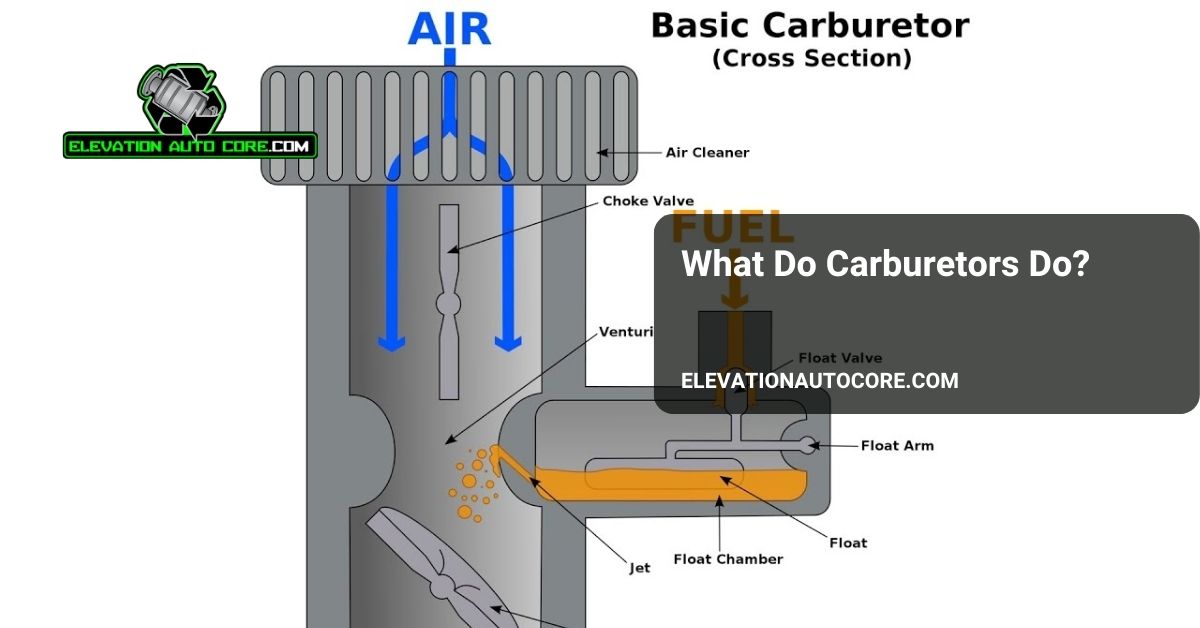

Key Components Of A Carburetor

Four main components help a carburetor’s operation. The float chamber stores fuel and maintains a constant supply for proper mixing. The venturi creates a pressure drop, drawing air into the carburetor for mixing with fuel. Jets are designed to control the amount of fuel released for precise air-to-fuel ratios. The throttle valve adjusts air intake, allowing you to control engine power output directly. Each part works together to deliver the ideal air-fuel mixture necessary for engine function.

How Carburetors Work

Carburetors control the air-fuel mixture in older engines, ensuring efficient combustion. By maintaining this balance, they directly influence engine performance and fuel efficiency.

Air Fuel Mixing Process

A precise blend of air and fuel enters the engine through the carburetor. Air passes through the venturi, creating a pressure drop that draws fuel from the jets. The throttle valve then regulates the amount of this mixture reaching the engine, adjusting power and speed. Fuel atomization also occurs in this process, breaking down liquid fuel into finer particles for improved combustion.

Types Of Carburetors

Different carburetors cater to exact engine designs. Downdraft carburetors use gravity to direct the air-fuel mixture downward, common in older cars. Sidedraft carburetors operate horizontally, fitting compact engine layouts like motorcycles. Updraft carburetors, where air-fuel flows upward, suit early engine models or small machinery. Dual or triple-barrel carburetors enhance performance by supplying increased fuel to high-powered engines during acceleration.

Benefits And Limitations Of Carburetors

Carburetors provide a practical solution for managing air and fuel mixtures in older engines. Their design offers both advantages and challenges, making it essential to understand their benefits and limitations.

Advantages Of Using Carburetors

Carburetors operate without reliance on complex electronics, making them simpler and easier to repair. You can tune them manually, offering flexibility in performance adjustments. They are cost-effective compared to modern fuel injection systems, particularly in vehicles with older engine designs. Classic cars often rely on carburetors, retaining their authenticity and original performance characteristics. Carburetors function effectively in engines designed for lower fuel pressures, ensuring reliable operation in less advanced systems.

Common Issues With Carburetors

Carburetors may face problems with precise air-fuel mixture control, especially under varying conditions. Inefficient fuel atomization in carburetors sometimes results in poor combustion and reduced fuel efficiency. Moving parts, such as the throttle valve and jets, are prone to wear and clogging, which affects performance. It’s possible for carburetors to deliver inconsistent engine responses during sudden throttle changes. In comparison to fuel injectors, carburetors struggle to meet modern emission control standards, making them less viable in newer vehicles. Regular maintenance becomes necessary to prevent buildup and ensure smooth operation over time.

Modern Alternatives To Carburetors

Technological advancements have introduced more efficient systems to replace carburetors. These alternatives enhance engine performance, fuel efficiency, and emission control in modern vehicles.

Electronic Fuel Injection (EFI)

Electronic fuel injection systems precisely deliver fuel to the engine. Sensors in an EFI system measure parameters like air pressure, engine temperature, and throttle position. Based on this data, the engine control unit regulates the fuel amount for combustion. Unlike carburetors, EFI eliminates manual adjustments, ensuring consistent performance in varied conditions.

Engines with EFI start more reliably in cold weather. The system also optimizes fuel use, leading to better mileage and reduced emissions. Common in modern vehicles, EFI has largely replaced carburetors in newer designs.

Transition From Carburetors To EFI

Shifts from carburetors to EFI systems transformed automotive engineering. Carburetors, once standard, could not meet stricter emission and efficiency standards. Governments introduced regulations in the 1980s, driving manufacturers to adopt EFI in passenger cars.

The change improved engine output and enabled precise control of air-fuel mixtures under all conditions. While carburetors required frequent tuning for optimal performance, EFI systems minimize maintenance. Though older vehicles with carburetors remain iconic, EFI dominates today’s automotive market.

Conclusion

Understanding the role of carburetors gives you valuable insights into the mechanics of older engines and their maintenance needs. Whether you’re restoring a classic car or exploring how engines function, carburetors remain a fascinating piece of automotive history.

While modern fuel injection systems have taken over, carburetors still hold their charm for enthusiasts and those who appreciate their simplicity and hands-on tuning capabilities. By grasping how they work and the challenges they present, you can better appreciate their contribution to engine performance and the evolution of automotive technology.